Aseptic Processing: Working with Biosafety Cabinets

Understand the fundamental principles of working with biosafety cabinets, and specifically the role of Class II BSCs in contamination prevention. The module includes airflow visualization, essential under EU GMP Annex 1 requirements and provides the user with practical examples of the skills, best practices and behaviors required when working with BSC’s.

Duration: 30 Mins

Description

Our eLearning module Aseptic Processing: Working with Biosafety Cabinets is designed to provide a comprehensive understanding of the fundamental principles and best practices involved in working safely and effectively with biosafety cabinets (BSCs). Biosafety cabinets are critical containment and protection devices in laboratory and manufacturing settings, playing a pivotal role in preventing contamination and ensuring the safety of personnel, products, and the environment – a key requirement of a contamination control strategy as per EU GMP Annex 1.

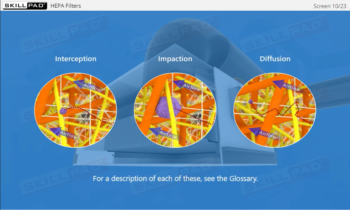

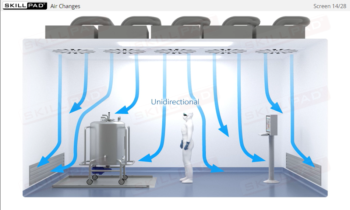

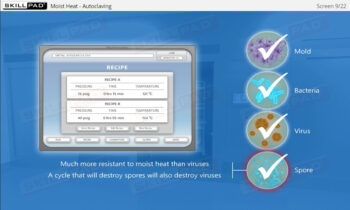

To begin, the module explains the concept of a biological safety cabinet, its operating principles, and the major components of a Class II BSC.

The module then focuses on the three stages of working in a Type II BSC : pre-use preparation procedures, best practices when working in a BSC, and post-use cleaning and disinfection procedures.

Firstly, users will learn how to prepare the cabinet for use, including cleaning and disinfection procedures, preparation of equipment and materials, and airflow and pressure checks.

Participants will then explore best practices for working in a BSC, gaining insights into the behaviors and techniques that are crucial for minimizing contamination risks. Through interactive elements and practical examples, these best practices are described and demonstrated, ensuring users are well-equipped to apply them in a workplace setting.

Finally, the post-use cleaning and decontamination procedures for a BSC are described. Knowledge and implementation of these procedures is essential to ensure the ongoing effectiveness of the BSC and the safety of personnel.

In summary, Aseptic Processing: Working with Biosafety Cabinets is a comprehensive, multimedia-rich learning module that equips participants with the knowledge and skills necessary to work effectively and safely in biosafety cabinets.

Part of Annex 1 training requirements

Contact us to get more information on this modules

Learning Objectives

- Explain the concept of a biological safety cabinet (BSC).

- Describe the operating principle of a BSC.

- Identify the major parts of a Class II BSC.

- Describe the preparation steps for working in a BSC.

- Describe best practices for working in a BSC.

- Demonstrate best practices for working in a BSC.

- Describe post-use cleaning and decontamination procedures for a BSC.

Module Features

- Animations

- Voice Over

- Knowledge Checks

- Assessments

- SCORM/AICC compatible

- Full Screen