Aseptic Processing: Cleanrooms and Control Technologies

Cleanroom design, use, and operation in aseptic processing, and the role of associated contamination control technologies such as HVAC systems, HEPA filters, pressure cascades, and airlocks.

Part of Annex 1 training requirements.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

- Demonstrate a comprehensive understanding of cleanroom design, use, and operation in aseptic processing including the critical role of cleanrooms in preventing product contamination.

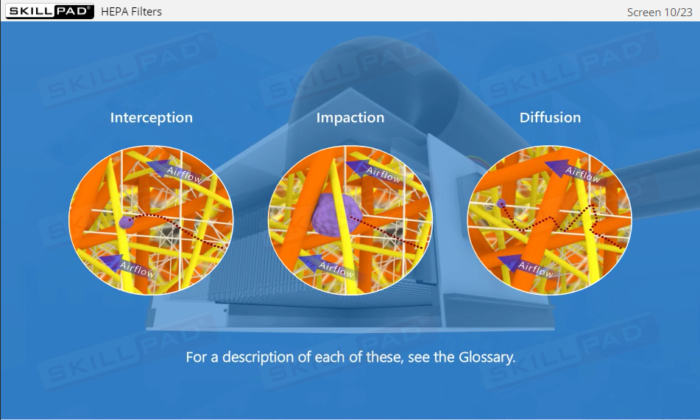

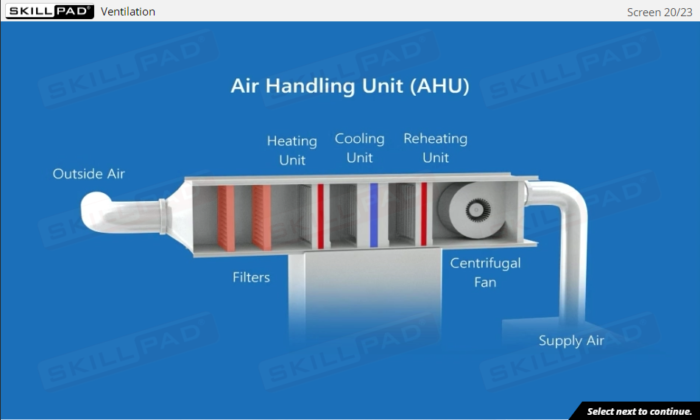

- Enhance your technical skills and knowledge by learning about the function of HEPA filters, HVAC systems, and airlocks.

- Apply your learning in practical scenarios through the module’s knowledge checks and explorations, reinforcing your understanding.

- Prepare yourself for industry regulations by understanding the grading of cleanrooms and the standards that govern them, ensuring compliance with regulatory requirements in your work.

Learning Objectives

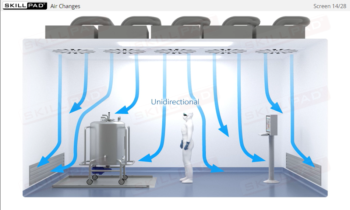

- Describe the basic structure of a typical cleanroom used in Aseptic Processing.

- Explain the purpose of a cleanroom in Aseptic Processing.

- Describe the function of HEPA filters in cleanrooms.

- Explain why cleanrooms are graded.

- List the four grades of cleanroom commonly used in Aseptic Processing.

- Explain how airlocks prevent contamination of a cleanroom environment.

- Describe the purpose of an HVAC system.

Keywords

- Airlocks

- Air Pressure

- Aseptic Processing

- Cleanrooms

- Cleanroom Design

- Cleanroom Standards

- Contamination Control Technologies

- Contamination Prevention

- Heating

- Ventilating and Air Conditioning (HVAC)

- HVAC Systems

- HEPA Filters

- Material Airlocks

- Personnel Airlocks

- Pressure Cascades

- Regulatory Compliance

- Quality Control

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen